42CrMo4 Steel Bars

Premium alloy steel bars manufactured to ASTM A829 & DIN EN10250 standards from our Mumbai facility. Ultrasonic tested bars with mill test certificates for critical applications in oil & gas, automotive, and construction machinery.

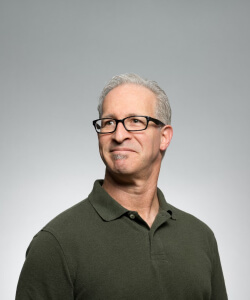

Suresh Mehta

Suresh Mehta